For many households and businesses across Zimbabwe, a borehole is a lifeline, offering a reliable, independent supply in the face of municipal water challenges. However, the common assumption that groundwater is naturally pure can be dangerously misleading. Borehole water, particularly in areas like Harare and Bulawayo, is frequently contaminated with minerals, heavy metals, and harmful bacteria.

To protect your family, your plumbing, and your appliances, understanding how to treat borehole water in Zimbabwe is essential. This process isn’t a one-size-fits-all solution; it requires a systematic approach, starting with diagnosis and moving to tailored purification technology. As one of the country’s leading water solution providers, Blue Steel Water has developed this comprehensive guide to help you achieve perfectly safe and clean water.

Click to get an expert water test now from $95 – https://www.bluesteelwater.com/water-testing/

The Reddit Post: A Stark Warning for Harare

1. Hard Water Minerals (Calcium and Magnesium)

These minerals are the most common issue. While not a direct health risk, they cause hard water, which leads to limescale buildup on kettles, geysers, and pipes. Over time, this scale reduces appliance lifespan, increases energy costs, and necessitates expensive plumbing repairs. A dedicated solution is needed to effectively manage water hardness.

2. Microbial Contaminants (Bacteria and Viruses)

Shallow boreholes or those located near septic tanks or farming run-off are highly susceptible to E. coli and other pathogens. These microscopic threats are silent, invisible killers that cause serious waterborne illnesses. Disinfection is a critical step for any untreated borehole supply.

3. Heavy Metals and Chemical Pollutants

This is the most alarming threat. Due to industrial activity, mining, or natural geology, groundwater can contain dangerous concentrations of heavy metals such as mercury, cadmium, and arsenic. These pose long-term health risks and are often tasteless and odourless. Standard filters cannot remove them, requiring advanced treatment technology.

Step 1: The Foundation of Treatment – Professional Water Analysis

You cannot treat a problem you haven’t identified. The first and most critical step in borehole water treatment is a professional Water Analysis in Zimbabwe.

A certified laboratory test provides a detailed breakdown of your water’s chemical and biological composition, including:

- Total Dissolved Solids (TDS) and pH levels.

- Hardness levels (to size a water softener).

- The presence and concentration of heavy metals.

- The presence of coliform bacteria.

Based on these results, the experts at Blue Steel Water can design a cost-effective and compliant treatment strategy guaranteed to solve your specific problem, ensuring you don’t overspend on unnecessary equipment.

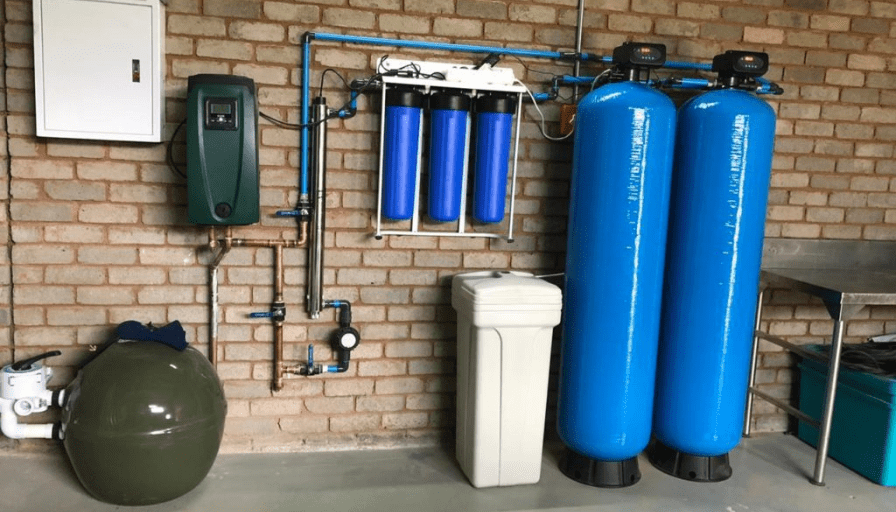

Step 2: Selecting the Right Water Treatment System

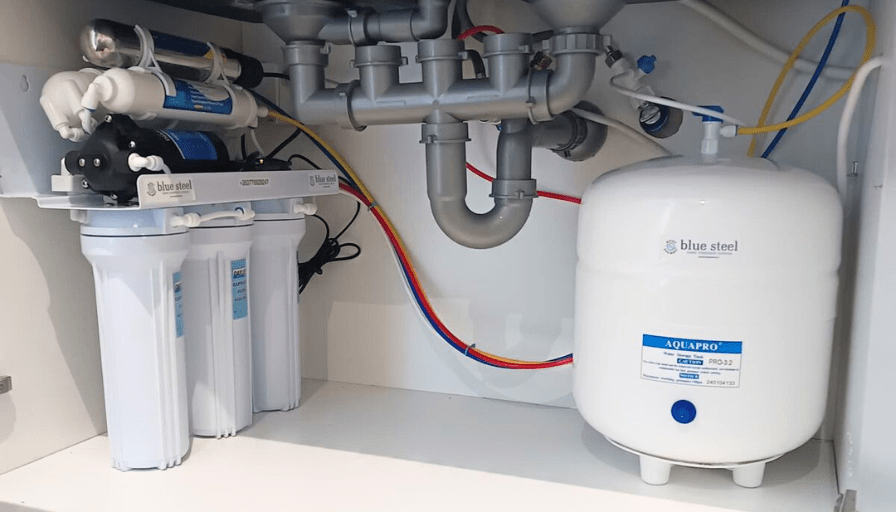

1. For Pure Drinking Water: Reverse Osmosis (RO) Systems

For absolute purity and the removal of the most dangerous contaminants, a Reverse Osmosis (RO) System is the gold standard. RO works by forcing water through a semi-permeable membrane at high pressure, effectively stripping out up to 99.9% of all total dissolved solids, including:

- Heavy metals (mercury, lead, cadmium).

- Chemicals (nitrates, fluoride).

- Dissolved salts and residual bacteria/viruses.

RO systems are typically installed as a final barrier to provide safe, potable water, especially for drinking and cooking.

1. For Pure Drinking Water: Reverse Osmosis (RO) Systems

If your water analysis indicates high levels of calcium and magnesium, you need a Water Softener System. These units use an ion-exchange process to remove the minerals that cause scale. Installing a water softener will:

- Extend the life of your geyser, dishwasher, and washing machine.

- Reduce your soap and detergent consumption.

- Keep your plumbing free-flowing and prevent costly breakdowns.

3. For Sediment and Clarity: Filtration and Disinfection

Most systems start with pre-filtration. Sediment filters remove sand, dirt, and visible particles, protecting the more delicate RO membranes and softeners.

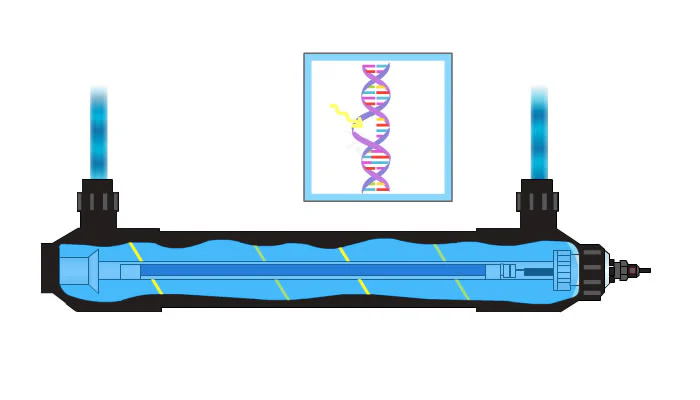

If bacterial contamination is present, a UV sterilisation system is typically used. UV light effectively neutralizes bacteria and viruses without adding chemicals, ensuring your water is microbiologically safe before it reaches your tap.

Chemical Sanitisation (Blue Steel Water’s Option): For stored water (tanks) or borehole disinfection, a chemical sanitiser is often used. Blue Steel Water’s Free²col is a popular chlorine-free sanitiser that uses copper-sulphate to control bacteria, algae, and fungi in the water supply. It is effective for keeping borehole and stored water safe to drink without the taste or odour of chlorine. It is dosed directly into the storage tank and requires a contact time to work.

Need More Information?

Do you need more infomation on our reverse osmosis system? Contact Blue Steel Water’s experts for advice tailored to your needs in Zimbabwe.